- EN ACT

- DE USR

In cooperation with the specialised Canadian company Beyond Energy Services & Technology Corp., STREICHER Drilling Technology GmbH offers European customers in the oil and gas industry know-how, equipment and service for Managed Pressure Drilling (MPD) projects. This partnership provides access to the latest technology in the field of managed pressure drilling for oil, gas and geothermal applications. Extensive MPD experience on a wide range of projects ensures efficient and reliable solutions. Streamlined logistics with centralised maintenance support and manufacturing facilities ensure smooth processing. Our MPD engineering support accompanies the entire life cycle of a well, or project, and ensures high quality standards underpinned by industry certifications. Our team consists of highly experienced personnel who ensures tasks are carried out competently and safely.

The International Association of Drilling Contractors (IADC) defines Managed Pressure Drilling (MPD) as an “adaptive drilling process used to precisely control the annular pressure profile throughout the wellbore. The objectives are to ascertain the downhole pressure environment limits and to manage the annular hydraulic pressure profile accordingly”.

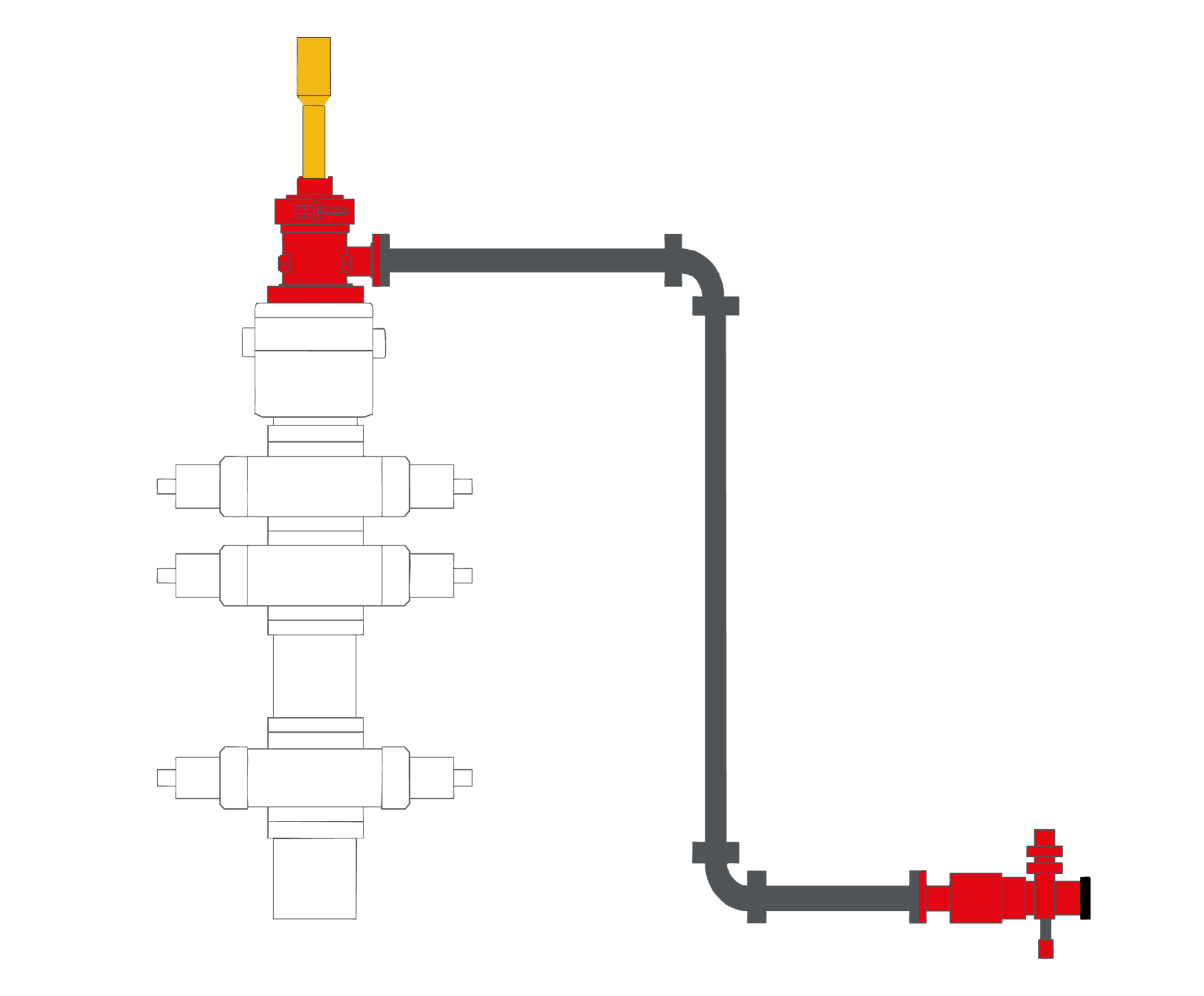

MPD is a much better and more efficient way to control the pressure profile in the well. It is possible because an MPD system creates a closed circulating system instead of the open one used in conventional operations.

In conventional operations, the system is open to the atmosphere on the top. There’s no ability to control pressure from the surface.

In MPD, a Rotating Control Device (RCD) seals the annulus against the drill pipe, allowing pressure to be applied on surface without any fluid spill. This allows for the use of gas as a fluid.

Drilling choke valves precisely control the pressure on the surface, allowing for the necessary changes in the pressure profile along the wellbore.

Conventional Drilling requires a change in mud weight for the entire well to change the bottomhole pressure conditions; while Managed Pressure Drilling (MPD) utilises additional surface equipment that allows closed-loop drilling and application of desired Surface Back Pressure (SBP) in the annulus to rapidly change downhole pressure conditions.

MPD offers a more controlled and adaptive approach, allowing operators to manage downhole pressure more precisely, enhance drilling efficiency and mitigate risks, making it a valuable tool in optimising drilling operations in challenging geological environments.

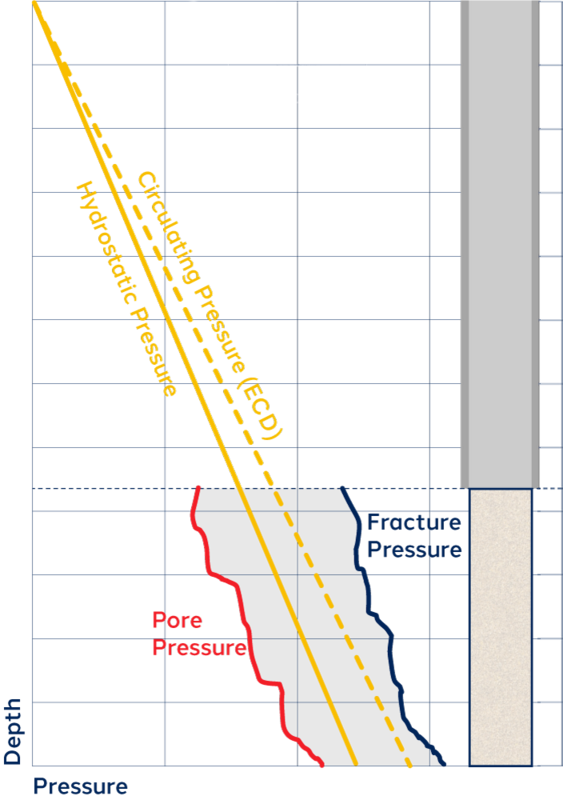

Both profiles need to be zero at surface in Conventional Drilling.

In conventional drilling, the well drilling system is open to the atmosphere at the top.

This creates two profiles:

One of the limitations of an open system is that the pressure profile always starts at zero at surface.

There is also a difference in the pressure at the bottom caused by the added pressure when pumps are on.

Both profiles can have similar bottom hole pressures.

MPD enables the driller to adjust the surface pressure in order to fit the drilling annulus pressure profile within the drilling window.

Pressure of hydrocarbons within the pores of a hydrocarbon reservoir. Pore pressure is at times the hydrostatic pressure which is exerted by the water column from the depth of a hydrocarbon formation up to the sea level.

Pressure at which stress-induced enlargements of the wellbore cross-section occur. When a wellbore is drilled, the material removed from the subsurface is no longer supporting the surrounding rock. As a result, the stresses become concentrated in the surrounding rock and the borehole walls can collapse into the hole.

Pressure at which the formation rock will break and allow fluids to flow inside.

Pressure of fluids present in a hydrocarbon reservoir. This pressure is usually exerted by a column of water on sea level from the depth of a hydrocarbon reservoir inside the earth’s surface.

The Drilling Window defines the operating range for the well to be drilled to the target depth and completed safely. It’s crucial because drilling is a complex process, and operating outside of the drilling window can lead to problems like wellbore instability, fluid losses, or even a blowout.

Oil and gas wells are drilled through several formations that have different pressure trends.

Drilling must be performed in a way that does not cause any of the following:

Well flowing oil, water or gas in an uncontrolled fashion (formation or pore pressure)

The formation collapsing, closing into the hole that was just drilled (breakout pressure)

Breaking (fracturing) the downhole rock, causing all fluids used to drill to be lost in the hole (breakout or fracture pressure)

These three pressures define the window in which the pressure created by the drilling fluid can exist within, without causing problems.

Wells are designed so that every time the drilling window is narrowed down to almost zero, a new casing string is set; this allows drilling to target a particular group of formations at the time, where determined hydrostatic and circulating pressure profiles can be maintained as to not exceed the defined drilling window boundaries.

MPD helps maintain wellbore stability by controlling the annular pressure profile. This is crucial in preventing issues such as wellbore collapse or kicks and lost circulation, which can occur in unconventional or challenging formations.

MPD allows for real-time monitoring and control of wellbore pressure, reducing the risk of kicks (uncontrolled influx of formation fluids) during drilling operations. By adjusting the backpressure, operators can mitigate the risk of formation fluid entering the wellbore.

In some drilling scenarios, the pressure window between pore pressure and fracture pressure is narrow. MPD enables precise control of downhole pressure, allowing drilling within these challenging pressure windows without compromising safety.

MPD can improve the overall efficiency of drilling operations by optimising the drilling parameters. Maintaining constant bottom-hole pressure makes it possible to drill faster and more accurately, reducing non-productive time and improving wellbore quality.

Managed Pressure Drilling can be used for underbalanced drilling, where the wellbore pressure is intentionally kept lower than the formation pressure. This helps reduce formation damage and improve reservoir productivity.

MPD is beneficial in geothermal drilling and high-pressure/high-temperature (HPHT) wells where the downhole conditions are extreme. The ability to precisely control pressure in such environments enhances safety and drilling performance.

MPD systems can be configured to minimise fluid losses to the formation, reducing the environmental impact and preserving drilling fluids. This is especially important in environmentally sensitive areas.

MPD is beneficial in extended-reach drilling, where maintaining stable wellbore conditions becomes challenging due to the long horizontal sections. It helps mitigate issues such as wellbore collapse and differential sticking.

MPD is beneficial in extended-reach drilling, where maintaining stable wellbore conditions becomes challenging due to the long horizontal sections. It helps mitigate issues such as wellbore collapse and differential sticking.

MPD enhances well-control capabilities, making it an important safety tool. Managing and controlling wellbore pressure reduces the risk of blowouts and other well-controlled incidents.

Our streamlined processes result in reduced logistical demands, safer operations and faster rig-up and rig-down. Experience enhanced efficiency and safer solutions with our innovative drilling solutions.

Backed by 24/7 engineering support and a highly experienced team, STREICHER Drilling Technology and Beyond Energy are your partner in achieving optimal performance and sustainability in drilling operations.

Managed Pressure Drilling (MPD) can save money through optimised drilling operations and improved efficiency. Here are several ways in which managed pressure drilling can contribute to cost savings for you as customer:

Reduced non-productive time (NPT): MPD helps minimise drilling issues such as kicks, losses, and wellbore instability, leading to less non-productive time.

Faster Drilling Rates: By using lower mud weight, MPD can improve the Rates of Penetration (ROP), thus improving the drilling time.

Use of lighter drilling fluid: The use of light drilling fluids, reduces costs and lowers operational impact.

Saving of casing strings within the fracture and pore pressure: Casing string savings are achieved by maintaining the Equivalent Circulating Density (ECD) within fracture and pore pressure limits, reducing material and operational expenses.

Drilling of long laterals minimising carbon footprint: Long lateral drilling enables the extraction of greater volumes from fewer wells, significantly reducing both costs and the carbon footprint.

Our MERCURY MPD™ package requires only a single truckload to the site, while our complete NITRO MPD™ package requires only 3 loads, compared to 5-6 loads for packages available in the market today.

Our integrated package requires less piping, and with our self-erecting systems, no crane is needed for rig-up and rig-down operations.

Beyond’s patented Walking System allows for an even faster rig-up and rig-down on multi-well pads, since modifying the existing system for well-to-well mobilisation is unnecessary. This system is offered with our complete NITRO MPD™ package.

For our NITRO MPD™ package, no additional interconnecting pipework is needed between the choke manifold and the separator. Only 2 skids are required for the manifold, metering system, separator, flare stack and pipe baskets.

No crew is required for MERCURY MPD™. For our NITRO MPD™, our standard crew for 24-hour operations consists of only 3 people on-site, covering site supervision, equipment maintenance, RCD operations and continuous pressure monitoring and management.

With our real-time operations control centre, our team of engineers assist our valued customers with designing their wells, supporting field operations 24/7, and monitoring all drilling activities while ensuring the technical integrity of the drilling operations.

The automated backpressure control system was designed by actual users with in-depth knowledge of MPD operations. It was created to deliver rapid and accurate pressure control while providing flexibility to operate under a wide range of conditions.

All our senior supervisory staff have 15+ years of global knowledge in MPD and UBD applications worldwide, ensuring your well is in the best hands possible.

Our experienced team has drilled over 2,500 wells in the last 8 years, ranging from multiphase operations to HPHT wells with no practical drilling window, under various conditions around the globe.